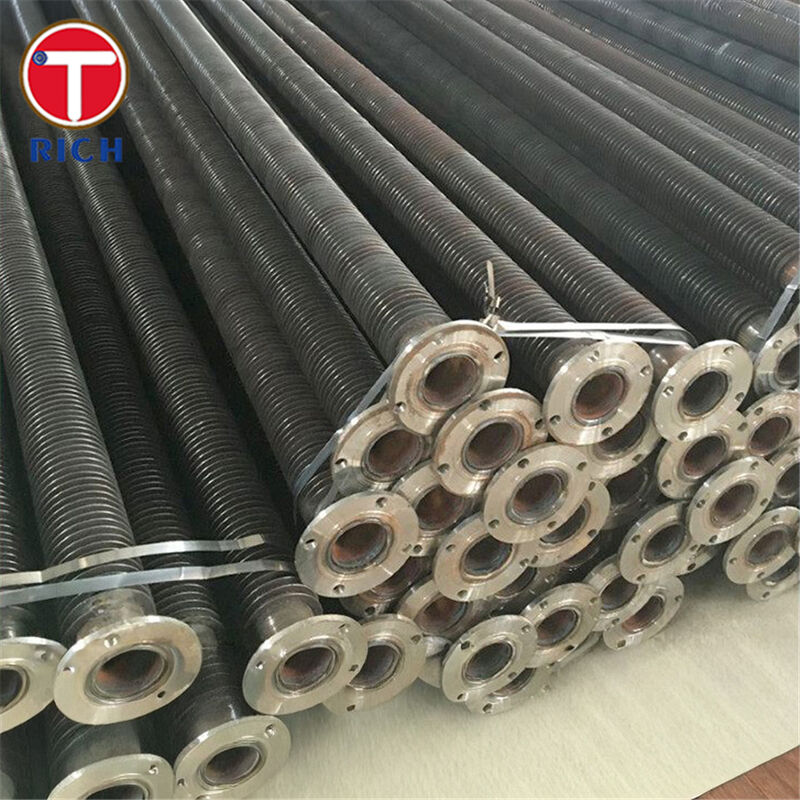

L-Fuß-Berohrung (Spiralgewickelt aus legiertem Stahl) für Wärmetauscher

Material

Dieses Produkt ist ein berohrter Wärmetauscher, bei dem ein Grundkörper aus legiertem Stahl (Kernrohr) spiralförmig mit einem Rippenband umwickelt ist, dessen Fuß in ein „L“-Profil geformt ist, daher der Begriff „L-Fuß-Rippe“. Die Rippen stehen unter Spannung und werden fest auf die Oberfläche des Kernrohrs gepresst, wodurch eine durchgehende Spiralrippe um den Außenumfang entsteht.

Spezifikationen

Typische Bereiche und Merkmale:

-

Kernrohrmaterial: nahtloser legierter Stahl (z. B. Güten wie ASTM A213 T11, T22; EN 13CrMo4-5; JIS STBA22; GB 12Cr1MoVG)

-

Außendurchmesser (AD) des Grundrohrs: ca. 16 bis ~50,8 mm (≈⅝″ bis 2″) für viele luftgekühlte berippte Rohre.

-

Rippenmaterial: typischerweise Aluminium- oder Kupferband, manchmal Stahl, in einer L-Fuß-Geometrie gewickelt.

-

Rippenhöhe: bis zu ~16,5 mm (max.) in vielen Fällen.

-

Rippendicke: ca. 0,4 mm bis 0,6 mm typisch für Aluminiumrippen.

-

Rippenabstand (Abstand): mindestens ca. 2,1 mm (≈12 FPI) und mehr, je nach Ausführung.

-

Typische Rohrlänge: bis zu ~18.000 mm (18 m) für einige Hersteller.

-

Betriebstemperatur (Rippenseite): bis zu ~150-230 °C typisch für L-Fuß-Berohrungen.

Hauptmerkmale

-

Die L-Fuß-Rippengeometrie stellt sicher, dass der Rippenfuß flach auf der Rohroberfläche aufliegt, wodurch der Wärmeübergang verbessert und somit die Wärmeübertragung erhöht wird.

-

Die Spiralwicklung bietet eine kontinuierliche Abdeckung um das Rohr und erhöht die äußere Oberfläche, die für die Wärmeübertragung zur Verfügung steht, im Vergleich zu blanken Rohren drastisch.

-

Die Konstruktion ermöglicht es der Rippe, als Schutzhülle für die Rohrwand (auf der Umgebungs-/Außenseite) zu fungieren und bietet einen gewissen Korrosionsschutz von der Luftseite.

-

Da die Rippen unter Spannung gewickelt und nicht in Rillen extrudiert werden, kann das Kernrohr dünner sein oder teurerer legierter Stahl verwendet werden, ohne dass das Grundrohr stark modifiziert werden muss.

Unsere Vorteile

1. Bleiben die Rippen unter thermischer Belastung und Luftvibrationen mit hoher Geschwindigkeit fest angebracht?

Unsere L-Fuß-Berohrungen verwenden eine kontrollierte Spannung beim Wickeln des Rippenbands, um einen festen Fußkontakt auf dem Rohr zu gewährleisten und ein Lösen unter Start-Stopp-Zyklen, Vibrationen oder thermischen Schocks zu minimieren.

2. Ist die L-Fuß-Rippe die richtige Wahl (im Vergleich zu LL-, KL-, eingebetteten Typen) für meine Aufgabe?

Ja—wenn Ihre Rippentemperatur auf der Luftseite moderat ist (z. B. bis zu ~230 °C) und Sie eine kostengünstige Lösung mit großer Oberfläche wünschen, bietet die L-Fuß-Konstruktion eine hervorragende Leistung. Für anspruchsvollere Aufgaben (höhere Temperaturen, sehr aggressive Atmosphären) können wir verbesserte Rippentypen (LL/KL) oder alternative Materialien empfehlen.

3. Wie sieht es mit Korrosionsbeständigkeit, Lebensdauer auf der Luftseite und Wartung aus?

Die Rippe dient dazu, die Rohrwand abzuschirmen, wodurch die direkte Einwirkung des Rohrs auf die Umgebungsluft reduziert und somit das Korrosionspotenzial verringert wird. Durch die Erhöhung der Wärmeübertragungseffizienz werden außerdem weniger Rohre für die gleiche Aufgabe benötigt, wodurch das Volumen des Bündels und die damit verbundenen Kosten für Struktur/Ventilator reduziert werden.

4. Rückverfolgbarkeit und Einhaltung der Materialgüte für den Hochtemperatureinsatz?

Unsere Kernrohre werden unter Verwendung anerkannter Standards (ASTM/EN/JIS/GB) mit vollständigen Werksprüfzeugnissen bezogen, und wir können zerstörungsfreie Prüfungen (Ultraschall, Wirbelstrom) oder hydrostatische Druckprüfungen nach Bedarf durchführen.

Warum uns wählen?

-

Wir liefern Grundrohre aus legiertem Stahl, die für den Einsatz bei erhöhten Temperaturen geeignet sind (Cr–Mo-Stähle) mit hoher Zuverlässigkeit.

-

Unser Rippenwicklungsprozess gewährleistet einen engen Kontakt zwischen Rippe und Rohr sowie eine gleichmäßige Geometrie für eine optimale Wärmeübertragung.

-

Wir bieten Standard- und Sonderabmessungen, Rippengeometrien und Oberflächenbeschichtungsoptionen, um den Anforderungen von Luftkühlern und Wärmetauschern gerecht zu werden.

-

Wir unterstützen die vollständige Dokumentation, Prüfung und Anpassung, um sie an Ihre Projektspezifikation und Ihren Qualitätsplan anzupassen.

Chemische Zusammensetzung

| Güte |

Standard |

C (%) |

Si (%) |

Mn (%) |

P (max) (%) |

S (max) (%) |

Cr (%) |

Mo (%) |

Hinweise |

| ASTM A213 T11 |

ASTM/ASME |

0,05–0,15 |

≤0,50–1,00 |

0,30–0,60 |

≤0,025 |

≤0,035 |

1,00–1,50 |

0,44–0,65 |

Gemeinsame Basis für berippte Rohre |

| ASTM A213 T22 |

ASTM/ASME |

0,05–0,15 |

≤0,50 |

0,30–0,60 |

≤0,025 |

≤0,025 |

1,90–2,60 |

0,87–1,13 |

Höheres Cr/Mo für den Einsatz bei erhöhten Temperaturen |

| EN 13CrMo4-5 (1.7335) |

EN 10216-2 |

0,10–0,17 |

≤0,35 |

0,40–0,70 |

≤0,025 |

≤0,010 |

0,70–1,15 |

0,40–0,60 |

Europäischer äquivalenter legierter Stahl |

| JIS G3462 STBA22 |

JIS |

≤0,15 |

≤0,50 |

0,30–0,60 |

≤0,035 |

≤0,035 |

0,80–1,25 |

0,45–0,65 |

Japanische äquivalente Güte |

| GB /T 5310 12Cr1MoVG |

GB |

0,08–0,15 |

0,17–0,37 |

0,40–0,70 |

≤0,025 |

≤0,010 |

0,90–1,20 |

0,25–0,35 |

Chinesischer Kesselrohr-legierter Stahl |

Mechanische Eigenschaften

| Güte |

Standard |

Zugfestigkeit Rm (MPa) |

Streckgrenze Re / Rp0,2 (MPa) |

Dehnung A (%) |

Hinweise |

| ASTM A213 T11 |

ASTM/ASME |

≥ 415 |

≥ 220 |

≥ 30 |

|

| ASTM A213 T22 |

ASTM/ASME |

≥ 415 |

≥ 205 |

≥ 30 |

|

| EN 13CrMo4-5 |

EN |

450-600 (t ≤16 mm) |

≥ 300 |

≥ 19 |

|

| JIS STBA22 |

JIS |

≥ 410 |

≥ 205 |

≥ 30 |

|

| GB 12Cr1MoVG |

GB |

470-640 |

≥ 255 |

≥ 21 |

|

Anwendbare Standards

Anwendungsbereiche

Allgemeiner Anwendungsbereich

Diese L-Fuß-Spiralwickel-Berohrungen werden hauptsächlich in luftgekühlten und Gas-Flüssigkeits-Wärmetauschern eingesetzt, bei denen ein Fluid im Inneren des Rohrs und Luft oder Gas über die Rippen auf der Außenseite strömt, um Wärme zu entziehen oder abzuführen.

Spezifische Verwendungsbeispiele

-

Luftgekühlte Wärmetauscherbündel in petrochemischen Anlagen

-

Ladeluftkühler oder Zwischenkühler in Gasverdichtungssystemen

-

Nachkühler für Gasturbinen oder mechanische Antriebseinheiten

-

Kondensatoren und Verdampfer mit luftseitigen Einschränkungen

-

Wärmerückgewinnungs-Economiser, die Rauchgas handhaben

-

Außenluftgekühlte Einheiten in Kraftwerks-Hilfssystemen

F: Sind Sie ein Handelsunternehmen oder ein Hersteller?

A: Hersteller, kann auch Handel betreiben.

F: Wie lange ist Ihre Lieferzeit?

A: Im Allgemeinen sind es 10-15 Tage, wenn die Ware auf Lager ist, oder es sind 30-40 Tage, wenn die Ware nicht auf Lager ist,

es ist nach Menge.

F: Stellen Sie Muster zur Verfügung? ist es kostenlos oder extra?

A: Ja, wir könnten die Probe kostenlos anbieten, müssen aber die Frachtkosten bezahlen.

F: Wie lauten Ihre Zahlungsbedingungen?

A: Zahlung=2000USD, 30% T/T im Voraus, Restbetrag vor Versand.

Wenn Sie eine andere Frage haben, können Sie sich gerne an mich wenden.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!